Specifications

LiquaPac HS Basket-Type Centrifuges

The American made LiquaPac HS centrifuge is designed for separating fine granular solids from aqueous or oil based fluids. The easy to clean removable liner has a large solids holding capacity and our patented feed accelerator and self-draining bowl ensure uncommon performance. The LiquaPac HS centrifuge is available in various configurations depending upon application requirements.

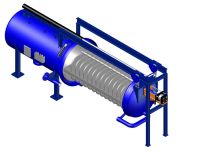

Turbo Basket-Type Centrifuges

Turbo Separators are the most efficient and highest performing liquid/solid basket-type centrifuges in the industry. Advanced engineering designs, such as feed acceleration and flow directing baffles, transfer maximum energy to the feed stream producing cleaner fluids and more recovered solids. Features such as the self-draining bowl and quick release cover locks allow for easy operation. Manual clean units have a large capacity removable plastic liner and automatic designs can remove up to 66 pounds/hour of solids. The product line also includes designs for coolant purification where oil removal is required.

Filter Leaves

Sanborn Technologies has been a leader applying centrifuge technology for coolant recovery and purification for over 30 years. These centrifuges are the most efficient devices available for removal of emulsified tramp oil in machining fluids. System designs incorporate automatic desludging centrifuges and are offered within many configurations including theIntegrated Fluid Recovery (IFR) Systems that combine pre-solids separation and biological control.

Verticle Basket Centrifuges

We offer the Sukhras line of vertical basket centrifuges which incorporate specifications and design from Sanborn. Centrifuges are available for either filtration or sedimentation applications. Applications include dye, pigments, bulk pharmaceuticals as well as industrial and biological sludges. Machines are available in a variety of metals and coatings.

Continuous Discharge Decanters

For high solids loading we offer the Noxon decanter centrifuge. Models range from a few gallons per minute up to 200gpm, all designed to discharge solids on a continuous basis. Decanters are found in applications with heavy solids loading where dry solids and good separation efficiency are required.